In January 2023, a raging fire destroyed the production plant of Spanish gourmet food company Cascajares. The company had two options: accept a total loss or rebuild in record time to save its crucial Christmas campaign and preserve the brand's identity. The choice was clear: rebuild and move forward. Cascajares worked with the leading engineering firm, TEICON, to rebuild the plant and restore the company's glory.

In less than a year, Cascajares and TEICON transformed a monumental challenge into an iconic case of innovation, technology, and collaboration. This is the story of how a functional and practical Virtual Design and Construction (VDC) approach, powered by BIM methodology and tools like SketchUp, Tekla, and Trimble Connect, made it happen.

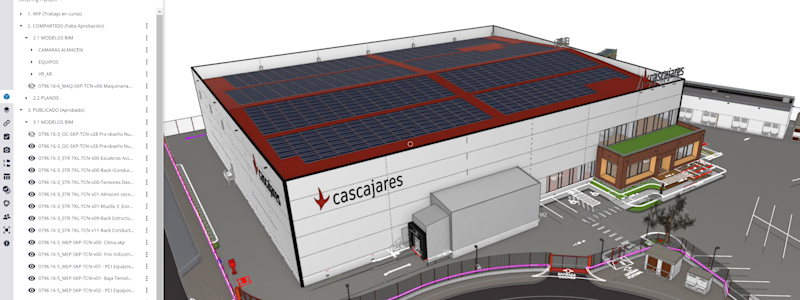

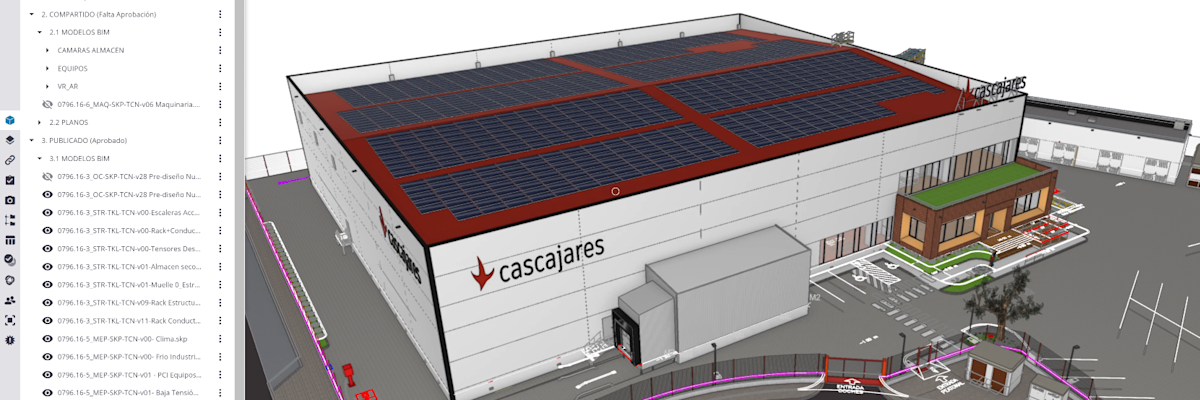

3D model of the Cascajares production plant in SketchUp.

Rebuilding with a plan

Reconstruction planning began with a set of complex, critical decisions that required clarity and determination. The client's main requirements were challenging:

Investment: €12,100,000

Deadlines: Phase I—production hall and changing rooms ready by October 2023 (8 months); Phase II—warehouse and offices completed by January-February 2024 (4 months).

Other: Comply with international sanitary regulations (IFS), design a modern and efficient plant aligned with Industry 4.0, and incorporate advanced digital technologies for management and maintenance.

A strategy for success

From the start, the team focused on strong coordination between the client, suppliers, and designers. They chose a prefabricated construction approach to minimize on-site time and integrated the BIM methodology to ensure interoperability and real-time information access through Trimble Connect.

The project planning included a BIM Execution Plan (PEB) that defined the work structure:

Use SketchUp for detailed modeling of architecture, civil engineering, MEP, and machinery disciplines.

Leverage Tekla to model the metal structure and fluids.

Employ Trimble Connect as the Common Data Environment (CDE).

Provide training for clients and suppliers on how to use the BIM tools.

A phased approach

Phase I: design and pre-construction

The team had to define designs and projects in record time. Thanks to early interoperability with suppliers and model exchanges, they began construction in less than two months. Detailed BIM design and modeling, focused on construction, were key to the project's success. The versatility of tools like SketchUp and Tekla provided the detailed modeling the team needed.

Installation rack in Tekla.

Phases, structure, and sections in LayOut.

Concrete structure model in SketchUp.

Phase II: construction and "as-built"

Coordination and interoperability among stakeholders during construction were critical. Using a Common Data Environment (CDE) helped manage and minimize unforeseen issues. With all teams working in a collaborative cloud-based environment (Trimble Connect) and a standard IFC format, this ensured interoperability, the identification and resolution of problems directly on the 3D model. Incidents could be assigned, commented on, and tracked in real time, improving coordination and minimizing errors or delays on site. Trimble Connect served as the central tool, enabling global management and team synchronization. This phase was defined by prefabrication, digital construction, and seamless collaboration.

Model of the inside of the factory in Trimble Connect.

IFC classification entities in SketchUp.

Phase III: operation and maintenance

Integrating BIM into operations allowed Cascajares to manage its facilities more efficiently. They used BIM models in Trimble Connect along with augmented reality (AR) and virtual reality (VR) to ensure better future implementation of new equipment and installations.

Equipment and machinery modeling in SketchUp.

SketchUp VR- Augmented reality

The Cascajares plant reconstruction is a clear example of how the Virtual Design and Construction (VDC) methodology and BIM models can make a difference in complex projects with demanding deadlines and requirements. The team tackled each project phase with effectiveness and efficiency using tools like SketchUp, Tekla, and Trimble Connect.

These tools stood out for their versatility, ease of use, and ability to coordinate teams in a collaborative environment. A well-defined strategy ensured the project met its deadlines and objectives, proving that technology, innovation, and collaboration can overcome even the greatest challenges.

Do you have a project with tight deadlines and complex requirements? Learn how SketchUp, Tekla, and Trimble Connect can help you achieve your goals.

About Cascajares

Driven by the vision of two young Spanish entrepreneurs, Alfonso Jimenez and Francisco Iglesias, Cascajares was founded 18 years ago. The company started by revitalizing the traditional Spanish capon, a premium poultry product. Their innovative concept was to offer semi-processed, high-end foods to the hotel, restaurant, and institutional (HRI) market, making a chef's job easier. This led to their slogan, "Queremos ser tu ayudante de cocina" (we'd like to be your assistant cook). Over time, Cascajares expanded its product line to meet the evolving needs of chefs.

About Teicon

TEICON INGENIERIA is an engineering firm with nearly 25 years of experience providing integrated and sustainable solutions. The company's diverse team of professionals works on all project phases, focusing on using modern tools and resources to lead industrial projects and meet client needs.

In collaboration with our partner Iscar Software.